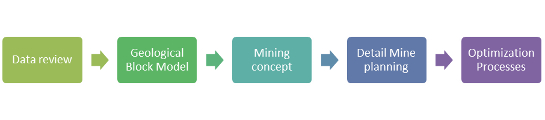

GEOVIA SURPAC

Nowadays, the deployment of modern planning software is one of the basic requirements for adequate and customer oriented execution of mine planning. FUMINCO uses GEOVIA SURPAC for planning tasks. It is, however, also possible to import and process data from other software solutions, such as DataMine Studio. GEOVIA SURPAC is a comprehensive CAD system that allows for the planning and management of opencast and underground mining projects in every phase of the process.

In the context of the creation of a geological model, the first step is to acquire and process a vast amount of geological data. Additionally, a check for plausibility is conducted. Detailed information about the deposit are usually gathered by drilling exploratory boreholes. This information is imported into GEOVIA SURPAC via database functions. The software intern drill hole database can process information about the course of the drilling and about the geology of the drilled hole. The next step in modelling a deposit is the creation of 3-D geological profiles.

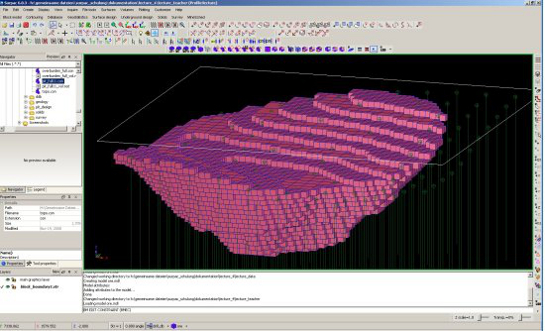

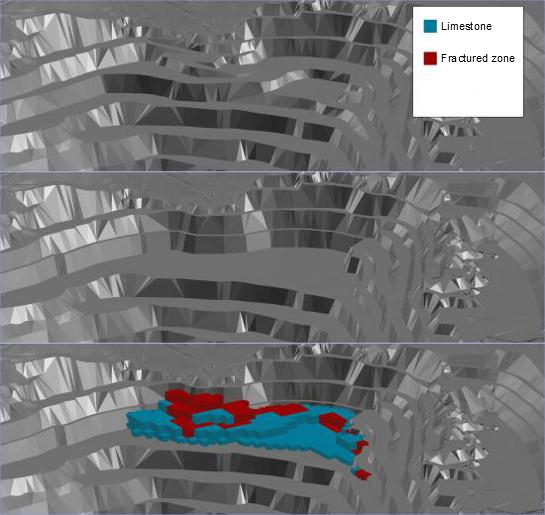

In order to be able to display a detailed map of the deposit, a so called block model is created based on the drill hole database and the 3-D profile data. The big advantage of a block model is that the deposit body is fragmented into geometrical entities, which allows for cutting or delimiting of the deposit body for different planning stages and thus for exact calculations of volumes.

The last step in the development of a geological block model is the implementation of the geological, hydrological, chemical and physical data from the drill hole database into the corresponding blocks by applicating of geostatistical methods such as "inverse distance" or "nearest neighbour". The implementation happens by using user defined block attributes, of which 256 can be saved per block. The work focus lies here on the mining material. In a coal deposit, for example, the following values are of importance for mine and power plant planning:

- Contained water

- Contained ash

- Contained Sulphur

- Calorific value

- Density

The geologial work is concluded by the creation of a comprehensive documentation and the presentation of the deposit parameters on the basis of so called theme maps and geological profiles. These theme maps are used for controlling and are the basis for the next step in the planning process. The following maps are needed:

- Overburden : Coal - ratio

- Quality maps (i.e. contained Sulphur) for each coal seam

- thickness maps (single and overall thickness)

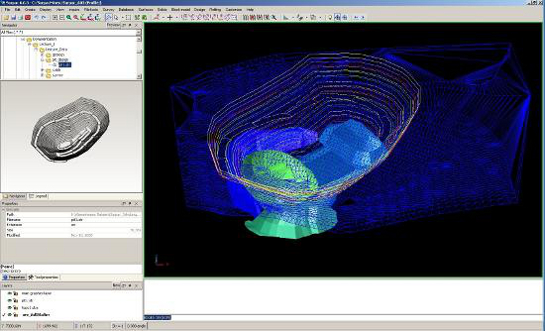

The 3-D block model is the basis of all further planning processes. The mine planning itself starts with the gathering of all available and relevant parameters, such as the clients planned annual production or the required slopes. In the context of the mine planning the next step is the development of the "final pit", which is the basis for a rough planning of the mining process and the required dumps. This first step of planning also includes a preliminary planning of transport routes. This povides a dependable basis for several different planning scenarios, which will be modelled in the further course of the project. Also theme maps can be created for every sector individually.

Based on the individual sectors multiple exposure scenarios will be developed in cooperation with the client. Several factors need to be taken into account when selecting the best scenario: The exposure location should be the place of coal in the least possible depth in order to be able to assure a good overburden / coal - ratio. The maximum final depth is another important factor. GEOVIA SURPAC allows the creation of multiple scenarios which can be evaluated based on mining and economic methods, which allows a custom made and optimal solution that can be presented to the client. The individual scenarios usually differ by different required annual productions or final depths of the pit.

When the best scenario was selected, a per-segment planning of mining and dump with proceeding stages from exposure to final pit is conducted. The masses of coal and overburden are calculated accordingly. The layout of the coal seams happens depending on the used equipment, the selection of which is conducted in cooperation with the client and based on the required production amounts and mining directions.

An optimisation of mining in open pits is accomplished by calculating centres of mass. The planning of transport routes and the locations of required infrastructure, such as location of crushers, is conducted accorrding to these centres of mass.

An ongoing controlling of each step in the planning process is primarily accomplished by the utilisation of a second planning software. The results of of the calculation of each mining stages volume based on the block model is verified by a second software: AutoCAD Civil 3D. This CAD software is not able to calculate the volume of individual seams and layers but can calculate the entire volume of a mining stage, which should be identical to the volume calculated with GEOVIA SURPAC. The entire planning of the dumps is conducted with AutoCAD Civil 3D.

The mine planning process is concluded by a comprehensive documentation of the results and the creation of maps and blueprints. For further information about the application of GEOVIA SURPAC please see the GEOVIA homepage.