Mining

Planning, expert opinions, approval procedures

Occupational safety and health

Health, safety, environment and quality

Further training

Labor and legal security

Use of geothermal energy from coal dumps

Smouldering fires in coal dumps occur when coal is oxidized by the oxygen of the air. In succession the developing heat in the dump lights the residual coal in the dumps of the coal mines. They are polluting the environment and require a long-term monitoring and special securing that needs to continue after the mining of coal has already ended.

Smouldering fires in coal dumps present not only a risk, but also a chance to use the thermal potential, which has been unnoticed: the stored heat in the dump and the occurring combustion gases were not used and released into the atmosphere. To develop the potential of the geothermal heat in the dump, the R&D Cooperation Project “Climate Protection: Thermal use of smouldering dumps” within the scope of the “klimazwei” program of the Ministry of Education and Research (BMBF) has been initiated by a research group from industry and sciences. Commissioned by the Unit of Technology of Fuels (Teer, RWTH Aachen University) FUMINCO performed “Field Laboratory Experiments, Modelling and Simulation of smouldering fires in coal dumps, Analysis of Optimum Stability of the dump”.

Aim of the project was the utilization of the thermal energy in smouldering fires in coal dumps combined with the reduction of greenhouse gases. The focus of the technical product development was the testing of production techniques and energetic use of the thermal dump heat. In a field experiment a heat-probe prototype and a product in the scale-up phase have been tested. This product should have ecological and economic advantages to the previous concept of the stability of the dump. Technical, legal, ecological and economic parameters have been examined to develop an alternative safety and energetic use concept. Besides the improvement of the knowledge on long-term safety on smouldering fires in coal dumps, concepts for the utilization of the thermal potential in generating electricity, cold or thermal heat were developed and tested.

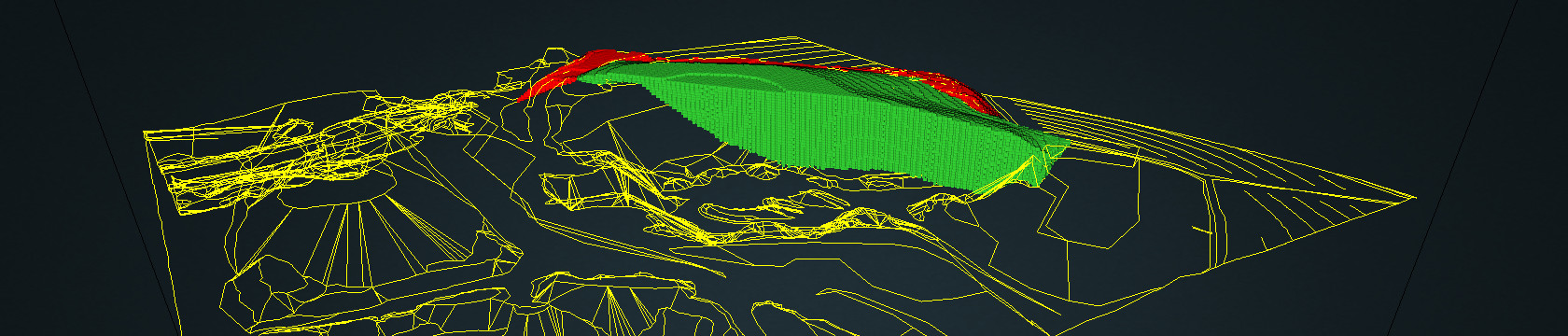

The focus of the work of the Unit of Technology of Fuels was based on the basic evaluation of laboratory and field experiments and the setting and calibration of a numeric simulation model. Based on our long experience in the area of simulation processes we supported the research work of the Unit of Technology of Fuels. Together we developed a 3D-Simulation of the smouldering dump on the basis of empirical generated algorithms. The calculations and the model of the smouldering fires in a coal dump were implemented in a simulation model.

NRW Experts' Report

In close cooperation with the consortium partner FUMINCO wrote parts of the “Experts’ Report including a risk study for the exploration and production of natural gas from unconventional deposits in North Rhine-Westphalia and the impact on the ecosystem especially the public drinking water supply”.

In the field of the exploration and production technology for Coalbed Methane and Shale Gas, FUMINCO applied the long-time experience amongst other things from the R&D Project “CBM Münsterland” to the experts’ report. Within the scope of the experts’ report following topics of the production technics were described in detail:

- Drilling Technics (description of the facilities, infrastructure)

- Drilling Concept

- Orientation and geometry of a well (Well Design)

- Casing and Completion of a well

- Stimulation Technics

- Drainage Technics

Projects

Since the founding of FUMINCO in 2006, we successfully completed a great number of projects in cooperation with our partners and clients. The following pages shall provide an overview over our portfolio by presenting selected projects. As consulting firm, the confidential handling of the clients data is our top priority. Hence, the presentations of the example projects have been prepared in close cooperation with our clients in order to acquire our clients approval to display them here.Business Area Mining.

In the context of our projects in the area of mining and in cooperation with numerous industrial partners, we were able to accumulate a great amount of experience , primarily in the areas of open pit planning and the layout of large recultivation areas. The spectrum of our services reaches from the geological modelling of lignite deposits in Serbia through the comprehensive mine planning and technical dimensioning of large ore and coal pits (Mauritania, Columbia, India) to the planning of large recultivation landscapes (India, Laos). In the area of the so called “Altbergbau” (historic mining), we conducted extensive digitalisation and interpretation work in collaboration with the RWTH Aachen University, which are the basis for the assessment of possible long-term mining damages in the “Ruhrgebiet” (Ruhr area).

Business Area HSEQ

Our second area of work – HSEQ – focusses on working safety in combination with quality management and environmental protection. Even though this area only recently became one of our working focusses, our employees constantly educate themselves in this area which assures the application of state-of-the-art practices for the provided solutions. An example of our services in this area is the development and deployment of a concept for an annual work safety schooling of the about 1.800 employees of the leading natural gas transporter Germanys.

Occupational Safety

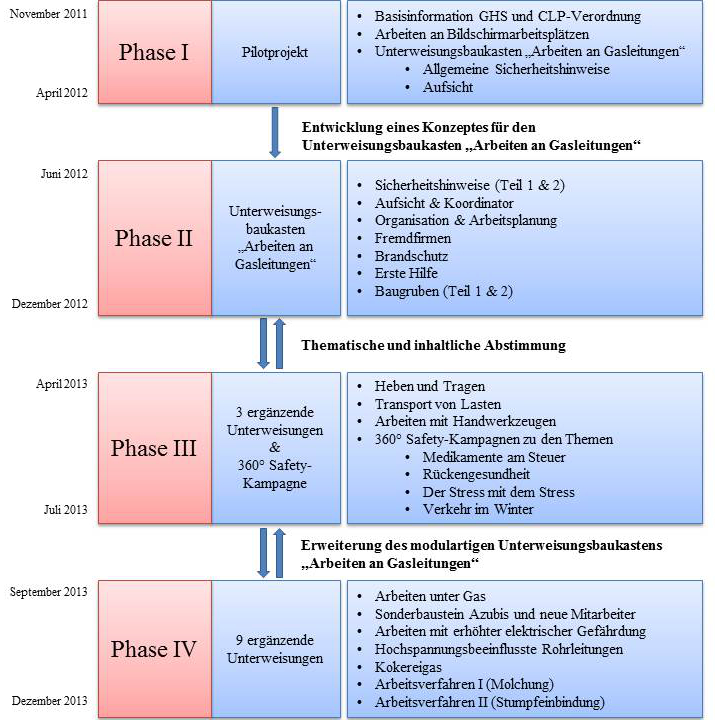

In November 2011 FUMINCO has been commissioned by the Open Grid Europe GmbH (OGE) with the “Pilot Project for preparation of instruction documentation” (Phase of Project I). During Phase I annual instructions for the staff have been developed, which are an addition to and summarize the operating instructions of OGE.

The concept and the results from project phase I form the basis for the further preparation of instructions in phase II to IV. While the development of the instructions, potential thematic and didactical improvement of the operating instructions of the client should be identified and completed.

Instruction Concept

The instruction concept includes an annual operating instruction of staff. It has a consistent, three-staged structure which was developed in phase I of the project.

The first step is the collection of all relevant sources, used for the development of the instruction documentation. Examples are different regulations, guidelines, standards or information material from insurance associations and the operating instructions of OGE.

The second step is a provided PowerPoint presentation for the annual instruction of the staff of the client. The presentation contains approximately 10 slides, which should be presented in a timeframe of 15 to 20 minutes. The main contents of the operating instruction should be conveyed with the presentation. Within PowerPoint short documentations of the topic are implemented.

Third step is an interactive quiz, which consists of five questions of each instruction topic. The quiz is realized in PowerPoint with a random generator that picks random questions out of a question pool and an automatic link to the next slide. The quiz offers self-control for the staff after the annual operating instruction. Preferably the revision of the topic should be done in teamwork. Within the team main features of the operation and individual experiences of the staff should be discussed.

Instruction construction kit "working on gas lines"

Phase I of the project has been successfully finished in April 2012. Contents of Phase I have been the operating instructions on “Basis information on GHS and CLP Regulations”, “Working on Workstations”, “Working on Gas Lines – General Safety Information” and “Working on Gas Lines – Supervision”. The documentation includes

- a Presentation,

- an interactive Quiz and

- all relevant sources for the operating instruction.

The instruction construction kit "working on gas lines" was developed in the project phases II to IV. It contains thirteen instruction modules actually that all consist of a presentation and a quiz. The themes of the instruction modules are the following

- Safety indication

- Supervisor & coordinator

- Organisation/communication

- Involvement/assignment of contractors

- Fire protection

- First aid

- Excavation pits

- working under gas

- special component trainees and new employees

- working with high electrical risk

- high-voltage affected gas lines

- coke oven gas

- working process I (welding (stamp))

- working process II (pig application)

360° Safety

Additional to the conventional instruction modules in cooperation with the client the so called 360° Safety-campaigns were developed. These campaigns contain a roundup of short texts and pictures about up to date HSE topics. The campaigns pop up on a chosen day on all computers when they are switched on. The aim is to sensitise the employees for a special topic by either shocking them ore making them thoughtful or laughing. In the frame of phase 3 four campaigns were developed dealing with drugs at the wheel, health of back, stress and driving in the winter.